Wind Turbine Vibration Causes – Rotating Equipments Vibration Analysis

Vibration is a common problem of wind turbine equipment, but not all vibration problems are caused by the bearing. Only when the vibration reaches an abnormal level, it can be taken as a sign of damage on your bearings.

BRS Bearing sorts out five major factors that may cause the wind turbine vibration.

1. Lubrication condition. Check if the bearings of the wind turbines are in good lubricating conditions. Poor lubrication will lead to excessive friction of the rotating equipment.

2. Installation and related components. Double-check if all components are correctly installed with the right tools and proper mounting procedures. The roughness and flatness of the mounting surface should be paid attention to. Check how to install and maintain yaw bearings and pitch bearings.

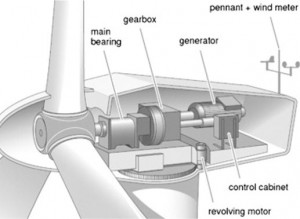

3. Check if there is a significant misalignment between the gearbox and the generator, which may cause considerable vibration.

4. Remove the pitch bearing or blade bearing and check its condition, if there is any damage on the surface.

5. Inspect the wind power generator gearbox, damage gears may cause vibration too.

If you are not a professional and wish to get help on a wind turbine vibration problem, please contact us at brs@brsbearing.com, our engineers are at your service for free.