Slewing Ring Bearing Types, Characteristics, and Applications

In recent years, with the continuous advancement of technology, China's machinery industry has achieved rapid development. This has also driven the market demand for slewing ring bearing. Slewing bearing is called the joint of the machine or the large-scale mechanical rotation bearing, which can withstand the combined loads such as relatively large axial load, radial load, and overturning moment during operation.

Slewing Ring Bearing Types

The characteristics of the turntable bearing should be analyzed according to its structure. Common types of slewing bearings including single-row, double-row four-point contact ball slewing bearings, double-row angular contact thrust ball slewing bearings, crossed cylindrical roller, and crossed tapered roller slewing bearings, three-row cylindrical roller slewing bearings, and combined structures slewing bearings.

Slewing Bearing Rings Characteristics and Applications

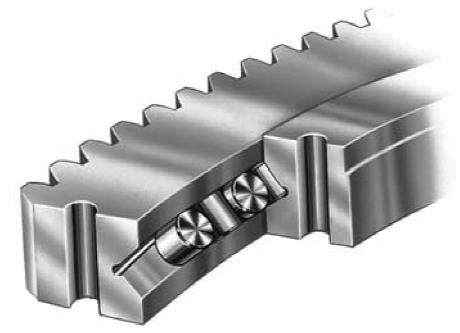

Single row cross roller slewing bearing

Crossed roller slewing ring is composed of two bearing rings, has a compact structure, high manufacturing accuracy, and small assembly clearance. The rollers are arranged crosswise, can support axial force, tilting moment, and relatively large radial force at the same time. So cross roller slewing ring bearings are widely used in transportation, engineering machinery, and military products.

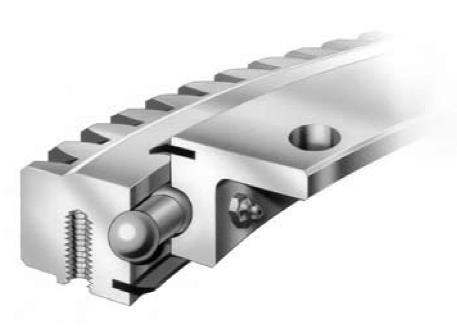

Single-row four-point contact ball slewing bearing

This type of slewing ring is composed of one inner ring, one outer ring, steel balls, and spacer retainers. It has a relatively compact structure, lightweight, four-point contact between the steel ball and the arc raceway, and can simultaneously bear axial and radial forces. Construction machinery such as rotary conveyors, welding manipulators, small and medium-sized cranes, and excavators often choose ball slewing bearings.

Compared with the cross roller slewing bearing, its characteristic is that the steel balls and the raceways are in four-point contact, so its rotation is more flexible. However, its load-carrying capacity and accuracy are not as good as the cross roller slewing ring.

Double-row ball slewing bearing

It is constructed with three bearing rings, so the steel balls and spacers can be directly placed into the upper and lower raceways. According to the stress conditions, two rows of steel balls are designed with different diameters. The load-bearing angle of the upper and lower arc raceways is 90°, which can bear great axial force and tipping moment. The axial and radial dimensions of the double-row ball slewing ring are relatively large and the structure is compact. It is especially suitable for loading and unloading machinery such as tower cranes and truck cranes.

Three-row roller slewing bearing

It is built with three independent rows of rollers, the upper, lower, and radial raceways are separated so that a load of each row of rollers can be accurately determined. A three-row roller slewing ring can bear various loads at the same time, has the largest loading capacity among all types of slewing rings. It has large dimensions and robust structure, especially suited for heavy machinery that requires larger diameters. Such as bucket wheel excavators, cranes, ship cranes, port cranes, molten steel moving platforms, and large-tonnage truck cranes and other machinery.

Light series slewing bearing

Light series slewing bearings have the same structure as ordinary slewing bearings, except that the inner ring or outer ring is ultra-thin. Lightweight and flexible rotation. It is widely used in food machinery, filling machinery, environmental protection machinery, wastewater treatment equipment, and other fields.