Slewing Bearing Lubrication

A suitable lubrication is essential for the longevity of slewing bearing's raceways and gears. The operating conditions such as loads, temperatures, speeds, vibrations, etc... determine the choice of lubricant.

Unless otherwise specified, BRS slewing rings are delivered greased. Usually it's No. 2 lithium-based grease or equivalent. However, the user may need to refill the new grease according to different operating conditions.

The slewing bearing raceway should be filled with grease regularly, but the greasing frequency varies according to utilization and environment. Generally speaking, the ball slewing ring need to be greased once every 100 hours of operation, while the roller slewing ring greased every 50 hours. For special working conditions, such as high temperature, high humidity, high dust, large temperature difference and continuous operation, the lubrication interval should be shortened. New grease must be added before and after the machine's long term shutdown.

How to lubricate slewing bearing?

During lubrication, rotate the slewing ring slowly to make sure the grease is evenly and fully applied. For slewing ring with gear teeth, the tooth surface should be frequently cleaned and applied the corresponding grease in time. Since there are many comprehensive operating factors, users can also choose the best grease according to specific requirements.

Pay attention to the operation of slewing bearing during use. If there are abnormal noise, or sudden increase of impact load or power, stop the machine immediately to check the trouble, and disassemble it if necessary. It is advised to take protective measures during use to avoid adverse effects caused by wind, rain, flooding and high temperature, and to prevent hard foreign objects from approaching or entering the tooth meshing area.

Always remember to check the sealing's condition. If the sealing lip is damaged, it should be replaced in time, if the sealing falls off, it should be reset in time.

Methods and tips for slewing bearing lubrication:

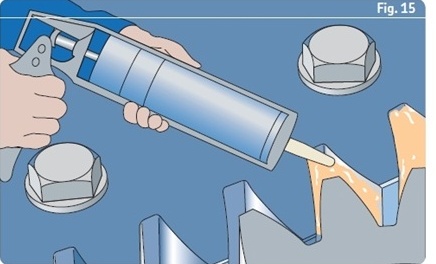

When adding grease to the slewing bearing, first fill the raceway. There is usually a grease nipple on the outer ring or end face of the slewing bearing, inject the grease into it with a grease gun. In the winter, add 2# lithium grease, and add 3# lithium grease in summer. In all cases, a lightt extrusion of new grease must appear at the protection seal lips.

During operation, the grease must entirely cover the flanks of the pinion and of the ring gear.

If your bearing is working under extreme conditions, please contact us(brs@brsbearing.com), we'll offer solutions accordingly.