Slewing Bearing Design and Material – What should be paid attention to?

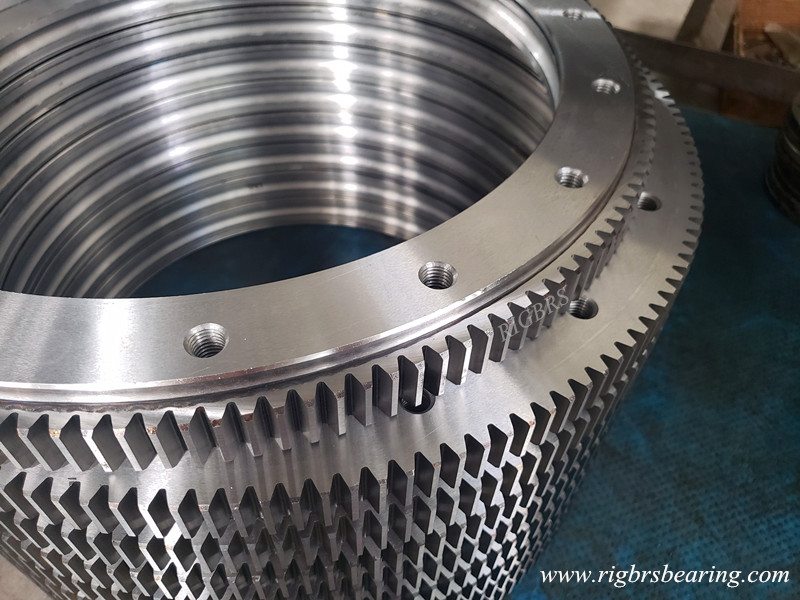

Slewing bearing design and material are interrelated. Slewing ring bearing usually refers to large size bearing that can withstand comprehensive loads, and can withstand large axial and radial loads and overturning moments at the same time. The slewing ring generally has mounting holes, internal or external gears, lubricating oil holes and sealing devices. Therefore, it can make the mechanism has a compact design, also very easy to install and maintain.

Slewing bearing design and material selection

When designing and manufacturing slewing bearings, designer and manufacturers often choose the material according to the following principles.

1. Operating temperature

Bearings working at room temperature are made of chromium bearing steel. And the designed working temperature range of slewing bearing is - 20° C ~ 80 ° C . When the working temperature is higher than 150 ° C and lower than 250 ° C, chromium bearing steel is also used, but special heat treatment is required (tempering at 200 ° C or 300 ° C is required). Besides, the lubrication grease for slewing bearing should be high temperature grease too. On the contrary, if slewing ring bearings are working under low temperature, special sealing and lubricant should be selected too.

2. Value of impact load

If slewing bearings work under strong impact load, chromium bearing steel is not suggested. High-quality carburized structural steel, impact-resistant tool steel or quenched and tempered structural steel are better. Here is an article about common materials for slewing bearing products. BRS can also produce custom design, our experienced technicians will offer you suggestions based on your requirements and applications.

3. Working environment

Bearings used in corrosive media must be made of corrosion-resistant steel or alloy steel with good corrosion resistance, such as stainless steel. But for slewing rings with special structure or size, maybe we can not process with the special material above, then surface treatment can also protect slewing bearings from rusting.