-

Part NO.

Open type:SHF25-XRB

-

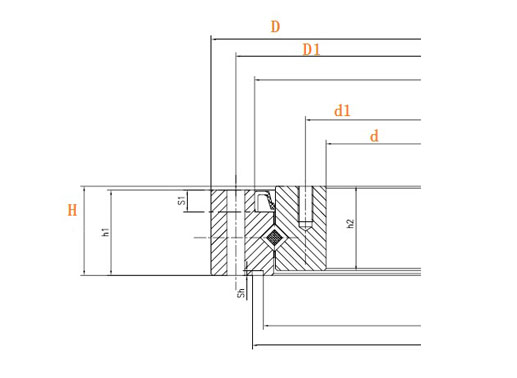

Dimension

d:66/68mm

D:110mm

H:20.7mm

-

Mounting

d1:77mm

D1:102mm

-

Basic Load Ratings

-

Equivalent Model

- Features

- Mounting

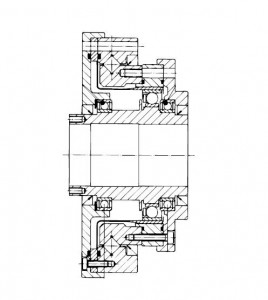

SHF-25 harmonic reducer bearing specifications:

Type of guide Roller Space retainer Yes Material GCr15 Standard lubrication method Grease lubrication Oil hole No Sealing Framework oil seal at one side Axial clearance -0.01 ~ 0 Radial clearance -0.01 ~ 0 Rotation accuracy P5 Working temperature -20℃ ~ 80℃ More SHF harmonic reducer crossed roller bearing models.

SHF25-XRB harmonic reducer output bearing features:

1. Integrated inner ring and outer ring.

2. Sustain radial, axial and moment loads at the same time.

3. High stiffness, high rotation accuracy and high loading capacity.

4. Ultra-thin and light weight, easy installation.

5. Hollow shaft structure, wires can pass through easily.

6. Specially designed oil seals with good sealing effect, ensure the cleaness of working envioronment.

7. Higher loading capacity version(full complement cylindrical rollers) available upon request.

FAQ

1. How to lubricate crossed roller bearings?

Unless otherwise stated, all BRS made SHF drive reducer crossed roller bearings are filled with proper amount of grease before delivery. So users can directly put bearings into application after receiving goods. Then after 1~6 months operation, bearings should be added with proper grease based on working conditions.2. What is the warranty of SHF-25 harmonic gearbox bearings?

BRS provide one year warranty for SHF crossed roller bearings that working under common working conditions. We have excellent after-sale service to help users during the installation and application of bearings.SHF-25 harmonic reducer bearing installation instructions:

1. Before installation, please clean bearing bracket, shaft, or other components,

make sure there is no burrs or rough edge.

2. Install the screws to connect crossed roller bearings with circular spline,

then install the screws to connect bearings with flex spline.

3. Install the wave generator and related components.