-

Part NO.

Open type:RA14008

-

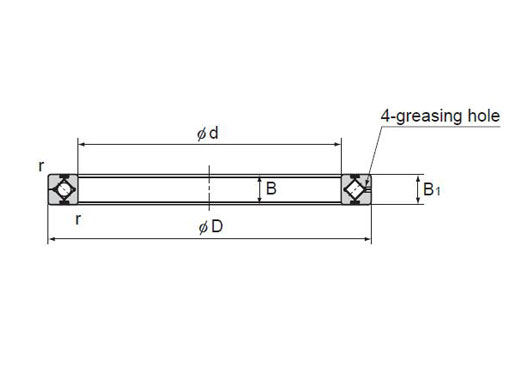

Dimension

d:140mm

D:156mm

B:8mm

-

Mounting

-

Basic Load Ratings

Cr:8.33kN

Cor:19.1kN

-

Equivalent Model

CRBS1408

- Features

- Mounting

RA14008 cross roller bearing specifications:

Type of guide Roller Space retainer Yes Material GCr15 Standard lubrication method Grease lubrication Oil hole Yes Sealing Oil seal at both sides Radial clearance CC0, C0 Rotation accuracy Radial/axial runout below 25μm Working temperature -20℃ ~ 80℃ * RA14008UU is two sides sealed type.

More RA cross roller bearing models

RA14008|RA14008UU crossed roller bearing features:

1. Integrated inner ring with separable outer ring.

2. Sustain radial, axial and moment loads at the same time.

3. High rigidity & running accuracy.

4. Ultra-thin section, space saving and reduce the overall weight of the device.

FAQ

1. Which precision grade and clearance of RA14008 bearing shall I select?

Below is the rotation accuracy and clearance standards, users can select based on their actual application and requirements. Your could also contact us for professional suggestions.Item Runout Tolerance Standards Higher Accuracy Radial runout of inner ring 25μm Available upon request Axial runout of inner ring 25μm Available upon request Item CC0 C0 Radial clearance -0.008~0μm 0~0.015μm 3. How to lubricate RA series crossed roller bearings?

Unless otherwise stated, all BRS made RA cross roller bearings are filled with proper amount of complex lithium grease before delivery. So users can directly put bearings into application after receiving goods. Then after 1~6 months operation, bearings should be added with proper grease through grease holes on the outer ring based on working conditions.RA14008 cross roller bearing installation instructions

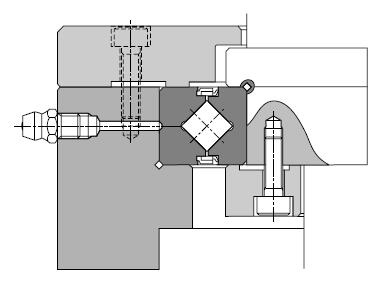

Cautions: For crossed roller bearings with split outer ring, when the rigidity of the mounting parts is not sufficient, stress concentration will occur at the contact area between the rollers and raceways, and the bearing performance will be deteriorated significantly.

Therefore, it is necessary to carefully examine the rigidity of housing and the strength of fixing bolts when a large moment will be applied.

1. Before installation, please clean bearing bracket, shaft, or other components, make sure there is no burrs or rough edge.

2. Fix the inner and outer rings in the axial direction by using fixing plates, etc.

3. Slightly loosen the fixing bolts of bearings outer ring during mounting.