-

Part NO.

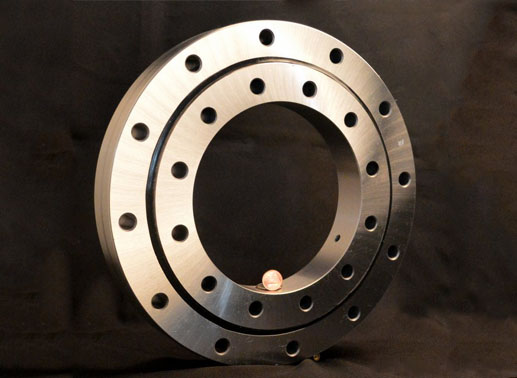

Open type:MTO-210

-

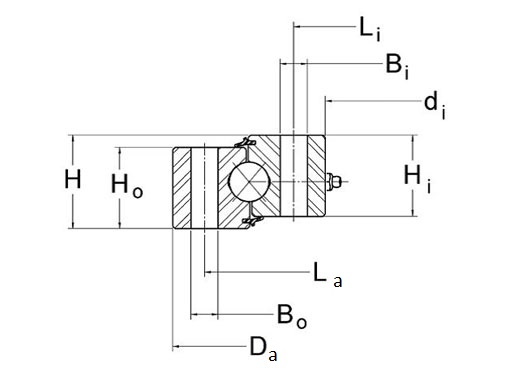

Dimension

di:210mm

Da:365mm

H:40mm

-

Mounting

Li:240mm

La:335mm

-

Basic Load Ratings

-

Equivalent Model

- Features

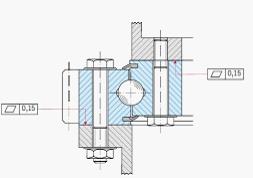

- Mounting

MTO-210 detail specifications:

Dimension in Inch 8.268*14.370*1.575” Rolling Elements Ball Space retainer Yes Material GCr15 Bearing steel / 50Mn Standard lubrication method Grease lubrication Lubrication Hole Yes Sealing NBR sealing at both sides Raceway Hardness HRC 50 ~ 60 Working Temperature -20℃ ~ 40℃ MTO-210 slewing bearings features:

1. Provide exceptional moment, thrust, and radial load capacities

2. Simple structure, can be applied in limited space

3. Easy installation, with mounting holes on both inner and outer ring

MTO-210 four point contact ball bearings installation instructions

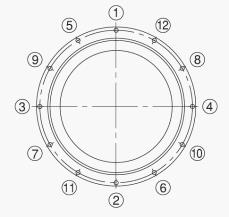

MTO-210 mounting holes:

– Inner ring mounting hole 20-φ14mm (0.562”)

– Outer ring mounting hole 16-φ14mm (0.562”)

1. Make sure the mounting surface is flat and clean, and free from burrs or

rough edge.

2. The unhardened zone is marked with an “S” on the slewing ring, it must be positioned outside the main load-carrying areas.

3. Commissioning of the slewing ring under sufficient load.

4. Adjust the backlash of gear and recheck it after final tightening of the bearing.

5. Fastening bolts. Place the bearing onto connecting structure and align the screw holes. Screw all the bolts in the holes first and follow the order as shown in diagram when tightening bolts in diagonally opposite sequence. Do not tighten bolts randomly.

6. Check the installation by rotating the assembled bearing arrangement. The torque should not show any excessive variation or “tight spots” during rotation.