-

Part NO.

Open type:567411

-

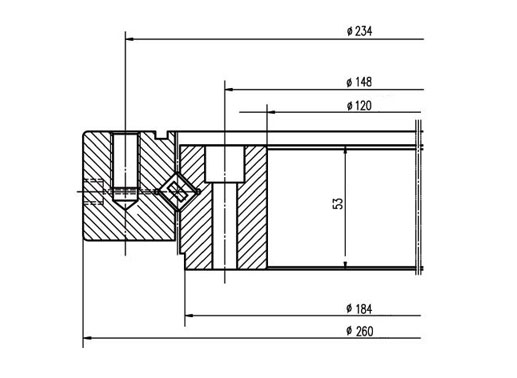

Dimension

di:120mm

Da:260mm

H:58mm

-

Mounting

Li:148mm

La:234mm

-

Basic Load Ratings

Cr:-kN

Cor:-kN

-

Gear Teeth

m:-mm

z:-mm

-

Equivalent Model

- Features

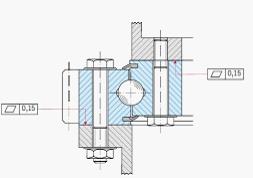

- Mounting

567411 crossed roller bearing specifications:

Type of guide Cylindrical rollers Space retainer Yes Material GCr15/50Mn Standard lubrication method Grease lubrication Oil hole Yes (outer ring) Sealing Without Surface treatment available Black oxide treated Rotation accuracy (axial/radial runout) Inner ring 0.006mm, outer ring 0.015mm Working temperature -15℃ ~ 80℃ 567411 slewing bearing structure is similar to RU crossed roller bearings, but it doesn’t have sealings and there is a groove on the end face of the inner ring.

567411 cross roller ring features:

1. High rigidity type slewing bearing with groove on the end face.

2. Support radial, axial loads and moment loads at same time.

3. Special surface treatment available, provide good anti-rust ability so as too extend bearings service life.

4. Processed with high precision CNC and grinding finish, which enable bearings have less friction, higher rotation precision and longer service life.

5. BRS only select high quality raw material, which can ensure bearings hardness and wear resistance.

6. Customized size or structure available.567411 small gearless slewing bearing mounting instructions:

1. Make sure the mounting surface is flat and clean, and free from burrs or

rough edge.

2. The unhardened zone is marked with an “S” on the slewing ring, it must be positioned outside the main load-carrying areas.

3. Commissioning of the slewing ring under sufficient load.

4. Adjust the backlash of gear and recheck it after final tightening of the bearing.

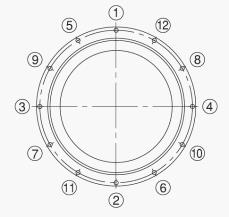

5. Fastening bolts. Place the bearing onto connecting structure and align the screw holes. Screw all the bolts in the holes first and follow the order as shown in diagram when tightening bolts in diagonally opposite sequence. Do not tighten bolts randomly.

6. Check the installation by rotating the assembled bearing arrangement. The torque should not show any excessive variation or “tight spots” during rotation.