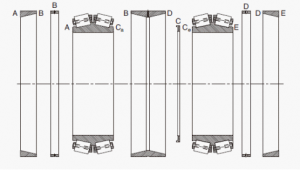

Premature Bearing Failure of Four Row Tapered Roller Bearings

Four row tapered roller bearings have become more and more popular among equipment designers because they can support heavy radial loads and axial loads at the same time, and very convenience to install and replace. However, compared with other type of bearings, four row tapered roller bearing has relatively high requirements on installation and application, so incorrect application may lead to premature bearing failure.

Bearing failure types

BRS has strict production and QC standards for four row tapered roller bearings. There are numbers or letters marked on each component of the bearing, showing the correct installation order. If users mount the bearing without following the instructions, bearing's clearance will be not in corfirmaty with the standards, and rollers will not be under uniform loads, which may lead to bearing failure of following types:

1. Wear of rollers or partial of the ring that undertake excessive loads

2. Bearing clearance too large or too small, leading to the overheating of bearing

3. Poor sealing effect allows contaminants go into the loading area and cause pitting damage.

Most premature bearing failure is caused by inappropriate installation, it has been proved by many experiments that correct installation will extend bearings service life.

Four row tapered roller bearings installation

Before installation, users should inspect if the dimension of bearing house, roll neck are within the tolerance. Install the bearing components according to the number or letter marked on the bearing, it is suggested to use a special lifting appliance to finish the installation.

Maitenance of four row tapered roller bearings

1. Users should keep the working environment clean, and check bearing's sealing effect at set intervals.

2. Choose proper greasing method according to application, if it's grease lubricating, do not fill in too much grease one time.

3. Check and clean bearing and related components at regular intervals.