Excavator Slewing Bearings Rotation Problem – Reasons and Solutions

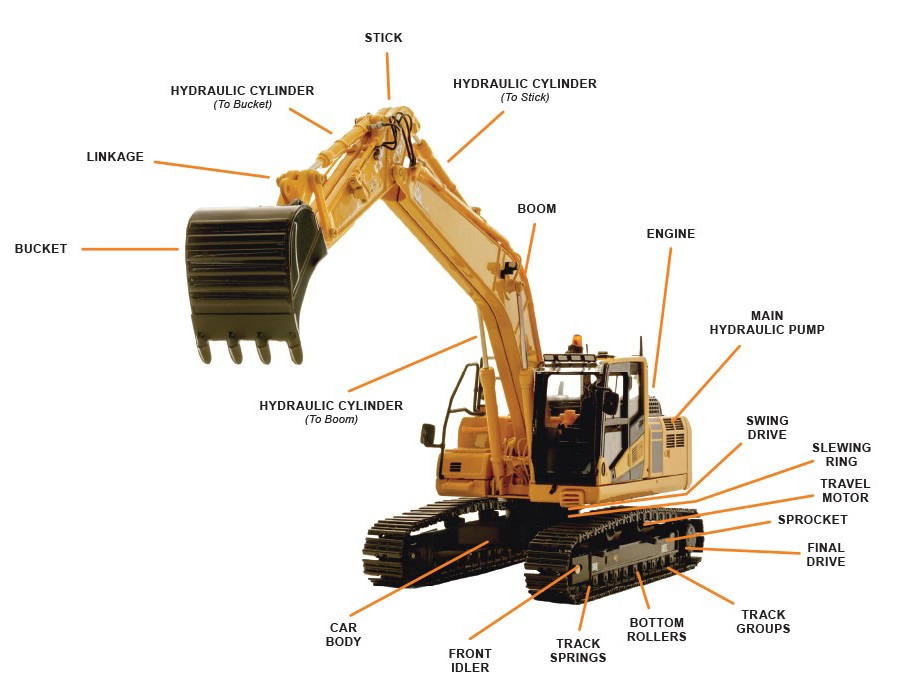

The slewing bearing is an indispensable part of the slewing device of the excavator. It is mainly used to support the mass of the upper cab, engines, etc., and bear the working loads. After long term operation under large loads or some poor working environment, excavator slewing bearings rotation problem may occur.

Major problems and soluctions for excavator slewing bearings inflexible rotation

1. Slewing ring gear deformation or broken cause stagnation or inflexible rotation

Solution: Repair the gear and re-weld the gear teeth.

2. Slewing rings sealing system has problem, which will cause contaminants entering the bearings so as to cause bearings stucking.

Solution: Clean up the slewing bearings.

3. If the newly purchased slewing bearing product rotation is not flexible. Check the production date, if the time is long and the climate is cold, there may be salt fog mixed in the raceway, which will cause the rotation resistance to increase exponentially and the slewing bearing will not work.

Remedy: Put some loads on the slewing rings(like video below) then tyr to rotate agian, if there is no other abnormality, it can be used normally.

4. Overload operation causes inflexible slewing bearing movement.

Solution: reduce the loads, or the slewing rings service life will be reduced.

5. Mounting surface is not flat

Solution: It is necessary to change the position of the platform and work in a flat position.

6. Lacking of lubricating oil will also cause excavator slewing bearings rotation problem. The lubricating grease may cause increased friction and increased resistance, which will cause unsmooth rotation.

Solution: Add lubricating oil of the same specification or replace lubricating oil completely. More info. regarding slewing bearings lubricating.

7. During installation, if the main engine mounting surface and the slewing bearing mounting surface are not well matched, it may lead to the deformation of the slewing bearing, and rollers will get stuck on the raceway. Besides poor meshing of the large and small gears, or foreign objects stuck in the large and small gears will also cause slewing rings rotation problems. Solution:

a. Re-machine the installation surface of the host to make the installation plane meet the requirements, or use the shim to help.

b. Adjust the gear backlash according to the requirements again, especially pay attention to the gear jump position.

c. Check to make sure there is no foreign matter in the meshing position of the large and small gears.

d. Replace a slewing bearing with a slightly larger clearance.