Crossed roller bearing mounting – Installation instructions and cautions

When talking to crossed roller bearing mounting, firstly we need to know the preparations before installation. What are the requirements for shafts and housings? What tools are needed?

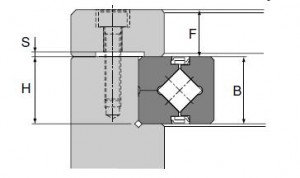

Crossed roller bearing housing and presser flange design

Since most crossed roller bearings belong to thin section precision slewing bearing, the rigidity of housing, presser flange, and related components need to be taken into consideration during mounting. For example, RB or RA cross roller ring has a split outer ring, so if the stiffness of the housing, presser flange, or fixing bolts is not sufficient, bearings inner and outer ring won't be evenly held. This will result in the deformation of the bearing when a moment load is applied. Meanwhile, the contact area of cylindrical rollers and bearing raceway will become uneven, which will significantly affect crossed roller bearings performance.

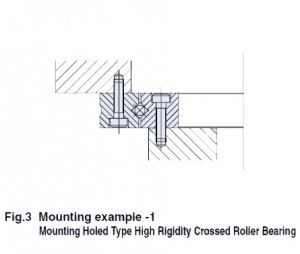

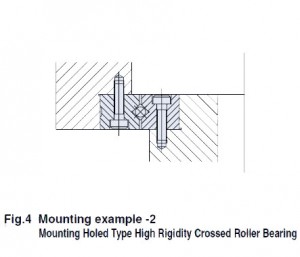

Installation Examples

PS: The thickness of the housing should be at least 60% of the sectional height of the bearing.

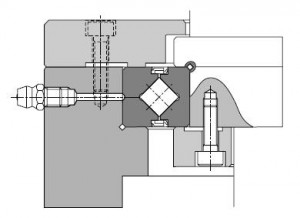

Crossed roller bearing mounting presser flange and presser bolt

F = B x 0.5 to B x 1.2

H = B(-0.1~0)

S = 0.5mm

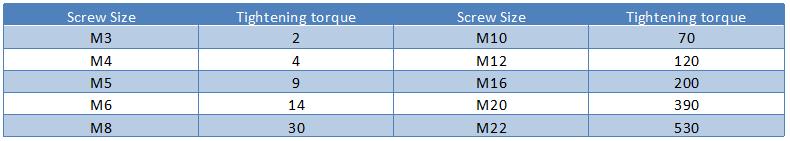

BRS suggest user select a steel-based material for presser flange. When tightening the presser bolts, firmly secure them using a torque wrench. The table below shows tightening torques for the housing and presser flanges composed of typical steel materials with medium hardness.

Crossed roller bearing mounting procedure

Inspection before mounting

Before installation, please clean bearing bracket, shaft, or other components, make sure there is no burrs or rough edge.

Install bearings into the housing or onto the shaft

Keep the bearing horizontal and insert the bearing into the bearing housing or shaft. If it is hard to install, use a rubber hammer to gently hit the bearing along its end face. Pay close attention to the hitting force as the bearing could be damaged if the force is too large. Afterward, the matching status of bearing and basic face can be examined by checking the noise of hitting.

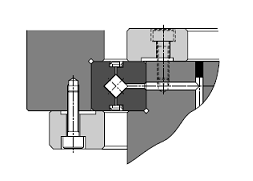

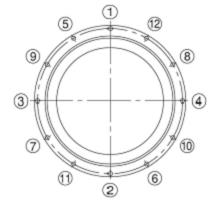

Install the presser flange

Place the presser flange(fixing plate) onto the bearing and align the screw holes. Screw all the bolts in the holes first and follow the order as shown in the below diagram when tightening bolts in the diagonally opposite sequence. Do not tighten bolts randomly.

Cautions

- Bearings have been adjusted to pre-load and filled with lubricant before delivery, users shall not disassemble bearings before installation. Please contact our after-sales staff for any problem during installation or application.

- During installation, please do not apply loads on the connecting screws, bolts, or rollers.

- The normal operating temperature of the bearing is -20℃~+80℃, please contact our technicians if it's over this temperature range.