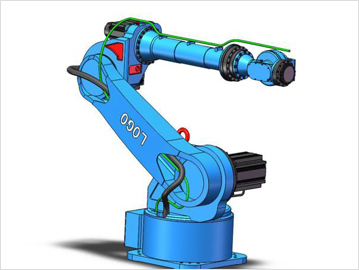

Industrial Robots

The development of modern industrial robots tends to be lightweight, and thin section. Since bearings must be installed in a limited space, the bearings for industrial robots need to be small in size and light in weight too. But at the same time, the robot's property such as high loading capacity, high rotation accuracy, high running stability, high positioning speed, high re-positioning accuracy, long service life, and high reliability needs to be secured by the matched robot bearings, so the bearings must have a good performance on loading capacity, precision, stiffness, low friction torque, long lifetime, and reliability as well.

Industrial robots bearing is the key component of industrial robots, it mainly includes six types: thin-section ball bearings, cross cylindrical roller bearings, harmonic reducer bearings, RV reducer bearings, linear bearings, joint bearings, and the first two types take the most market share.

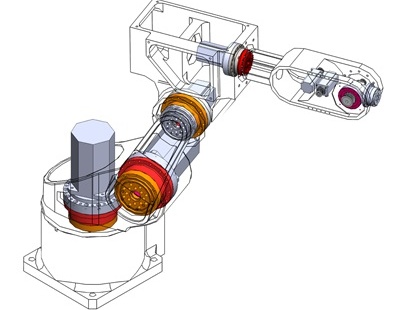

Classification of bearings for industrial robots

| Bearing | Structure | Application | Precision |

| Thin section ball bearing | Thin section four-point contact ball bearing Thin section angular contact ball bearing Thin section deep groove ball bear |

Robot joints | P5 |

| Thin section crossed roller bearing | Integrated inner/outer ring type, Integrated inner ring with split outer ring type Integrated outer ring with split inner ring type |

Manipulators, swiveling units of robots | P4 |

| RV reducer bearing | Angular contact ball bearing Tapered roller bearing |

Industrial robots | P4 |

| Harmonic reducer bearing | CSF crossed roller bearing SHF crossed roller bearing CSD crossed roller bearing SHD crossed roller bearing |

Joint units of robots | P5/P4 |