Bearing Problems During Operation – Reasons and Solutions

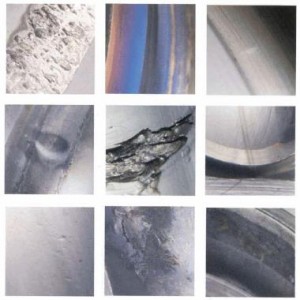

Though bearing belongs to precision processed products, it will have problems before and during applications. It's necessary to inspect bearings before installation and check its status regularly during operation. Below are common bearing problems users may meet during operation. Some is easy to identify and solve, the ealier you noticed the problem, the easier we can fix it.

Bearing Problems and Solutions

| Operation Status (Bearing Problems) |

Possible Reasons | Solutions | |

| Noise | Metallic Noises | Abnormal load | Adjust fitting and bearing clearance, adjust preloading, modify bearings shoulder position, etc |

| Poor installation | Improve machining precision of shaft and bearing house, Improve installation method and precision |

||

| Insufficient lubricant or unsuitable lubricant brand |

Supplement the lubricant, choose the right lubricant |

||

| Mutual contaction between the rotating parts |

Modify contact parts of seals | ||

| Regular Noise | Indentation caused by the contaminents between the raceway and rolling elements. |

Replace bearings, clean related parts, improve sealing and use clean lubricants |

|

| Fretting or fretting corrosion | |||

| Brinell indentation | Replace bearings and use the correct mounting method |

||

| Peeling and spalling | Replace bearings | ||

| Irregular Noise | Oversized clearance | Adjust bearing clearance and preload | |

| Invasion of contaminants | Replace bearings, clean related parts, improve sealing and use clean lubricants |

||

| Flaking | Replace bearings | ||

| Overheating | Too much lubricant | Reduce the amount of lubricant, choose grease with higher consistency |

|

| Insufficient lubricant or unsuitable lubricant brand |

Supplement the lubricant, choose the right lubricant |

||

| Abnormal load | Adjust fitting and bearing clearance, adjust preloading, modify bearings shoulder position, etc |

||

| Poor installation | Improve machining precision of shaft and bearing house, Improve installation method and precision |

||

|

Creeping on the fitting surface |

Replace bearing, adjust clearance, improve the sealing system structure |

||

| Too much friction caused by sealing device |

|||

| Large Vibration | Brinell indentation | Replace bearings and use the correct mounting method |

|

| Peeling and spalling | Replace bearings | ||

| Poor installation | Correct the verticality of shaft, bearing seat shoulder and end face of spacer |

||

| Invasion of contaminants | Replace bearings, clean related parts, and improve sealing |

||

|

Lubricant Leaking and Discoloration |

Too much lubricant | Use appropriate lubricant, clean bearings & parts and change lubricant brand |

|

| Invasion of contaminants | |||

If you can not find the related bearing problems from the above forms, or not sure about the status of your bearing, don't' worry, contact us (brs@brsbearing.com) and our engineers will be at your service.